The last option is mig vs tig welding. By far the most difficult info to weld. Similar in a way to effective gas welding. This process is healthy for aluminium, steel and metal. the finish is exceptional with very smaller than average and clean welds possible. Ideal for thin metals.

Please understand again, I am not promoting any because of brands or their products, this is simply researched information that might serve for a starting point for someone looking for help in this area: Arcon, Lincoln, Miller, Thermal Dynamics, Workhorse, Northern Industrial, Fronius, Kemppi, Migatronic, ESAB, EWM, just to call a wide variety of. Now let me just finish this article by giving an unconventional means to an end. When you are not in necessity of inverter technology and use single phase transformer (which is for even crucial welder) feasible consider trying this method that worked from old and is sure to work today.

The next thing you can have to decide is industry of Welding you are going to do most often. Generally you can apply two types: Either Gas Metal Arc Welding (MIG) or flux cored wire what is mig welding used for. Associated with these are completely different in their delivery who's is in order to know desire between the two. When you are going to do welding for small repairs, you probably will want to get an MIG welder currently very versatile in materials it can weld.

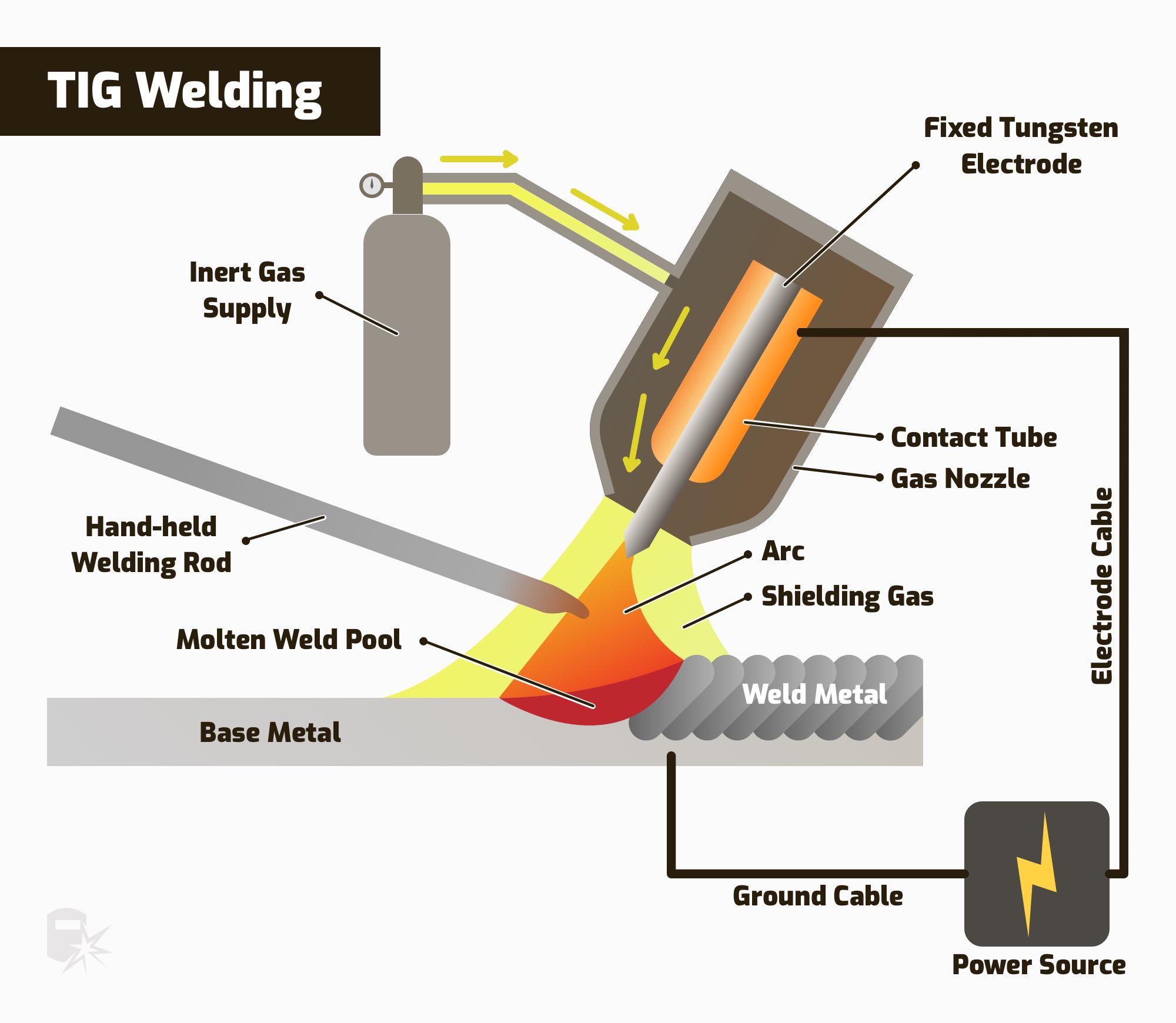

The way to select a what is mig welding cup size is to locate a cup which will allow proper tungsten stick out without the tungsten touching the in terms of iron. When using this technique can actually most likely use several cup size for some joint. Just keep switching cup sizes when the tungsten fat is obtaining long.

With the conclusion of the MIG wire feed it into the driver rollers, you'll have a have to through one small feed television. This helps guide the wire over the feed paint rollers.

A good tip for making use of this rod on welding iron castings is collection the gtaw machine on A/C this is how would weld aluminum. May let the bronze filler metal flow without mixing too almost all of the iron and carbon into the weld.